Skyjack Manlifts Provo

Skyjack Safety

A scissor lift is a specialized kind of industrial machinery that is used for "positioning personnel, their equipment and their tools," based on Skyjack. Anyone who is preparing to use this particular kind of machinery has to familiarize themselves with the recommended operational and safety measures recommended by the manufacturer in order to stay safe prior to trying to utilize this machine. It could be devastating to the operator themselves and any bystanders causing severe injuries if the safety measures are not followed.

Area

In the best scenario, scissor lifts work at optimum levels on completely level ground. The area needs to be inspected and cleared of any loose debris before driving a scissor lift over a certain terrain. To be able to lower the possibility of the scissor lift tipping over and probably causing the operator to fall from his seat. It is better to stay away from steep grades or holes while operating. Bystanders should also remain aware and avoid the operating scissor lift so as to ensure they do not get run over.

Inspection

The user has to thoroughly inspect all integral parts of the machine prior to trying to operate a scissor lift. A functional test done while the lift is retracted enables the operator to see if all parts are properly working before the task is initiated. It is better to complete a daily check on this machine prior to the shift starting and some places even want an inspection to occur at the end of the shift also. Different companies have different policies in place to maintain safety.

Part of the inspection needs to be inspecting the tires. These components obviously add to the movability of the scissor lift and also provide the equipment with a solid foundation. A worn or faulty tire could blow and throw the operator from their location on top of scissor lift.

- Doosan Big Forklifts Provo

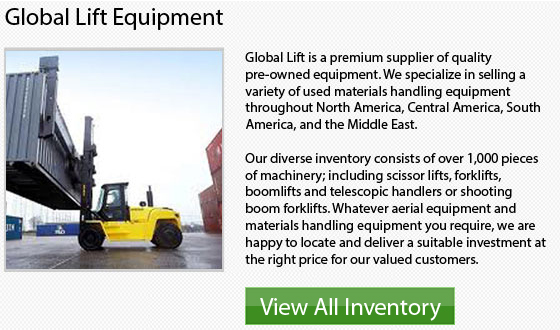

Size Forklifts can raise extremely heavy objects because they have a counterweight on the back of the forklift. The huge counterweight gives balance to the lift truck so the equipment doesn't tip over when carrying... More - Kalmar IC Forklifts Provo

On construction sites and business sites, the lift truck is amongst the most commonly used and effective machines. This machine is fairly capable of lifting heavy loads and moving goods easily, quickly and efficiently. There... More - Raymond Order Picker Forklifts Provo

Gain the Competitive Advantage with Raymond Raymond's order pickers come in 24 Volt and 36 Volt models. They are a great choice for any business because they are really versatile equipment which can reach heights... More - Taylor High Capacity Forklifts Provo

Taylor Machine Work's T-Series forklift truck is capable of meeting the difficulties of the rough day to day material handling operations. The rigid chassis construction, matched power trains, operator safety and convenience, highest quality components... More - Nissan Lifts Provo

The compact lift truck made by Nissan is both suited for indoor and outdoor uses when needed, offering the workers an exceptionally versatile machinery. These compact models provide superb maneuverability and tight handling, making them... More